Vande Berg Scales Blog

Welcome to our wonderful blog about Scales!

Call or Email us Today: 712-722-1181 | info@vbssys.com

Chaotic Product Labeling: Conveyor vs. Manual Scale

Chaotic Product Labeling, October 10, 2014

While many production lines run consistent product, there are also a good handful of plants that require chaotic product flow from their lines. In this case, chaotic product flow is referencing different types of product running on the same line rather than a uniform product. When comparing conveyor scales and manual scales, each method has unique benefits for chaotic product, so we’re going to examine the differences between them.

Manual Scales

When it comes to the standard weighing situation, conveyor scales tend to take the cake, but there are still situations where manual weighing might be a realistic solution. Think of a plant that handles offal products as an example. The offal is the leftover parts which are unused for standard cuts of meat, like the tongue, heart, or other organs. They are usually shipped to various other countries or places specializing in some sort of ethnic cuisine, so it is important that they are documented well. The offal handling is a smaller operation, and with so many different destinations and products, it is almost easier to manually weigh and label the boxes. This lets you be very specific with each box of offal that you handle. If you combine a manual scale with a labeling printer and controller, you can have a fairly efficient manual labeling system. You can weigh a box and input the product type into the controller to print out a specific label for that product. With the right operator, this can be very quick like an automated system, but it is lacking in consistency. Label placement isn’t necessarily uniform and handling time varies with employees.

Conveyor Scales

On the flip side of things, if you take the same operation and you size it up to a much larger scale, manual weighing just won’t cut it. This is where pre-identification would come in handy.

If you have a chaotic flow of products that requires speedy handling, a conveyor scale is a necessity. When paired with an automatic labeler,

it can find the product weight and have it printed on the label quickly and consistently. The question then becomes, “how do you accurately label

different products without stopping the lines to make labeling adjustments?” With pre-identification scanners, you can scan boxes or barcodes before

they get to the labeling section. These preliminary codes or labels can tell the controller what the product is so that it can pass on that

information to the labeler. A print-and-apply system can then print out a specific label to match that product and affix it to the box/package.

This requires no human involvement besides a little monitoring and maintenance every once and a while, making it the obvious choice for a larger operation.

There are reasons to consider both of these options, and we have systems available for both situations, so look around our blog or contact us to find out

what might work out best for your operation.

If you have a chaotic flow of products that requires speedy handling, a conveyor scale is a necessity. When paired with an automatic labeler,

it can find the product weight and have it printed on the label quickly and consistently. The question then becomes, “how do you accurately label

different products without stopping the lines to make labeling adjustments?” With pre-identification scanners, you can scan boxes or barcodes before

they get to the labeling section. These preliminary codes or labels can tell the controller what the product is so that it can pass on that

information to the labeler. A print-and-apply system can then print out a specific label to match that product and affix it to the box/package.

This requires no human involvement besides a little monitoring and maintenance every once and a while, making it the obvious choice for a larger operation.

There are reasons to consider both of these options, and we have systems available for both situations, so look around our blog or contact us to find out

what might work out best for your operation.See our Manual Box Labeling Systems

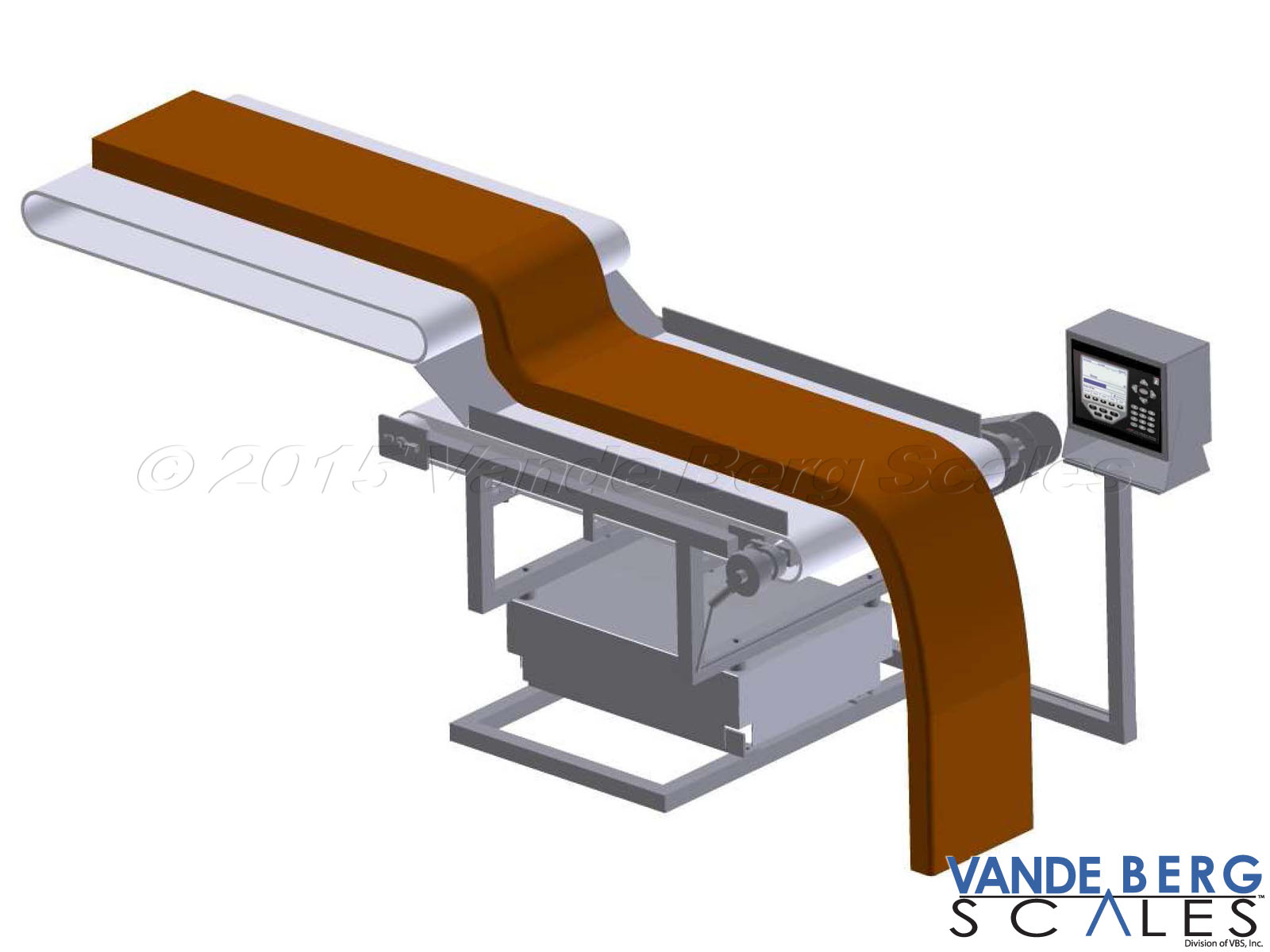

Flow Scales: The Best Way to Weigh Bulk Product

Flow Scales, October 29, 2014

While we spend a lot of focus on conveyor scales and checkweighers, they aren’t the only in-motion scale variants that we work with. The flow scale is a specific type of conveyor scale that comes in very useful when you aren’t really looking for individual weights as much as accumulated weights. The design of a flow scale is very similar to any other conveyor scale, but it handles the weighing process and the data that it processes quite differently. With a conveyor scale, the normal way of operating requires that only one product passes over the scale at a time.

The scale takes a number of weight readings as the product passes over it, and that allows the system to come up with an accurate weight average to assign to that product. On the other hand, flow scales are perfect for a plant that doesn’t need the weight of every product but still wants to know their daily totals. There are many industries, such as particle or aggregate product type, where this could specifically come in handy. When working with bulk product where weighing each individual piece is a useless endeavor, a flow scale is a great fit. Things like bacon bits or anything that comes in small chunks or pieces can’t be weighed on an individual basis because that would take a ridiculous amount of time and there wouldn’t be any gain out of it.

The flow scale works by taking weight readings every time a whole scale length has passed. This means that the scale weighs a scale’s length in product for every reading before allowing a new scale’s length in product to take its place. Summing all of these readings up gives you a total weight of the throughput for a given period of time. Having these weight totals helps a plant to understand its throughput which can in turn help management to know how efficiently their processes are working. With small product, there are many steps where you can lose product, so this data can aid in the analysis of those points of loss. Having data is important in any business, so if you deal with bulk product, this might be a good solution if you don’t have the information you are looking for.

See our Flow Scale Video

Contact VBS today!

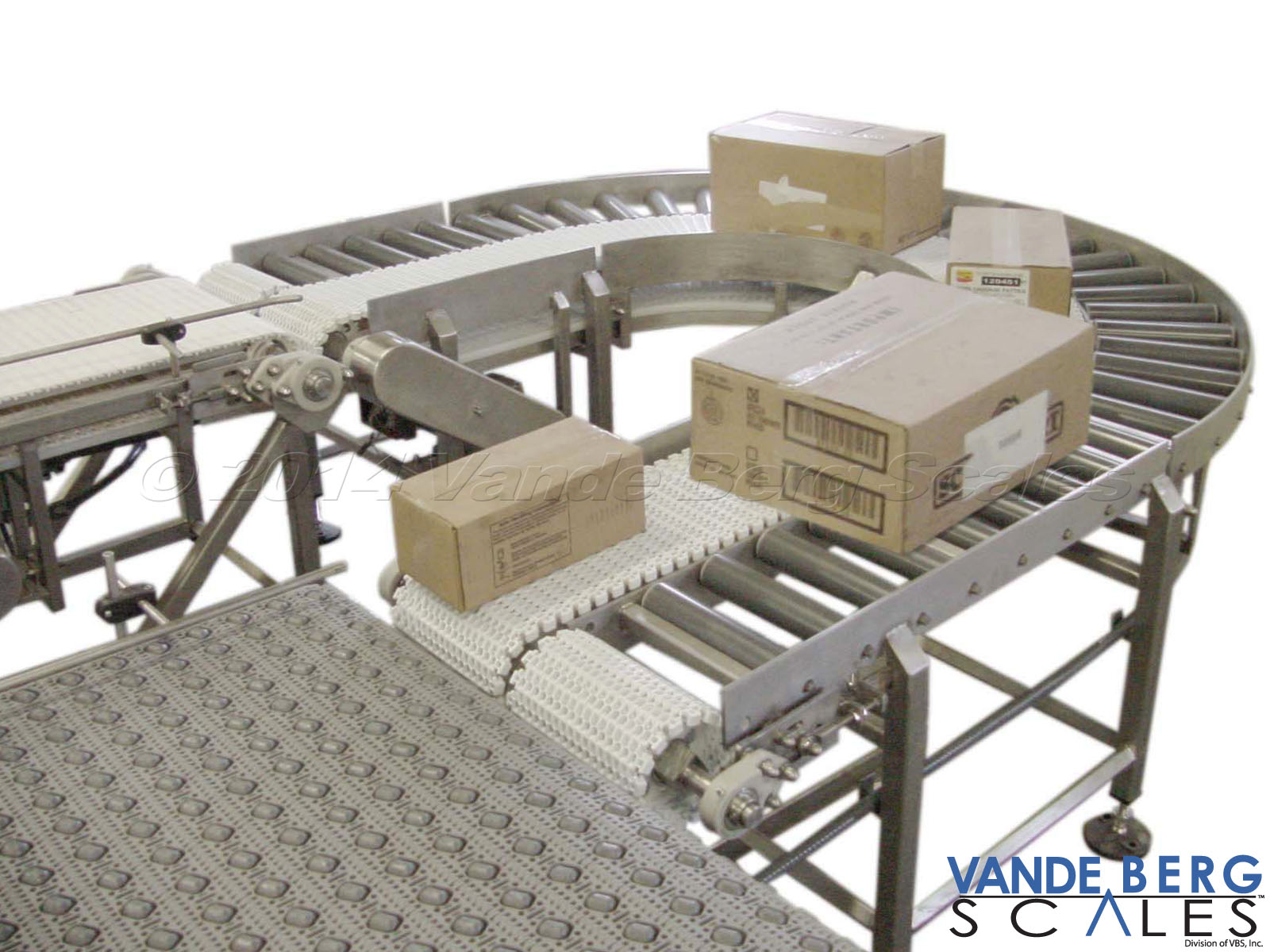

Making a Turn with Box Conveyor Systems

Turn with Box Conveyor Systems, October 28, 2014

We build conveyor systems for numerous different products, but some of the most interesting conveyor designs come into play when we are just handling boxes. Most industries handle boxes at some point or another, and moving them around can demand some inventive maneuvers in certain plants. In any given plant, you will find obstructions like pillars, walls, and other mechanical systems that a box conveyor might have to navigate around. This takes thinking outside of the box (no pun intended) and implementing different kinds of belting, structures, and mechanisms.

A common solution to this problem is to use multiple conveyors that run perpendicular to one another to go around obstacles. This is a fairly simple solution, but you are limited to 90 degree turns in between conveyors. If that doesn’t sound like an elegant enough solution, there is always the possibility of using a radius conveyor. A radius conveyor uses special modular belting which allows it to curve around the desired angle. This offers a much smoother turn, and it offers the possibility of turning a variety of angles.

It is easier to make a 180 degree turn in smaller space using the previous method, but we have been able to minimize the radius to a point where it can make relatively sharp turns. It’s possible that these turns change the orientation of your product in a way that interferes with a labeling process, but there are ways to deal with that as well. You can use a roller wheel for 90 degree rotations. When a box contacts one of these wheels, the leading edge is held against it by the conveyor flow and the box spins around it until it has made a 90 degree turn. At that point, the conveyor naturally pulls the box away from the roller.

In order to use a multiple conveyor system and retain product orientation while transferring between conveyors, you might need something like a speedup roller at the end of each conveyor. This would “grab” the box and launch it onto the next conveyor. Without it, the box would be pulled in two different directions at the transition, causing it to turn and alter with orientation. If subtle orientation adjustments are needed after a conveyor transition, you can use angled roller belting and a guard rail.

Angled roller belting can push a box diagonally on the conveyor. If you use this to drive the box towards a guide rail, it will straighten itself out once it makes contact with the side. Sometimes, you might even want to add small rollers to the guide rail to prevent friction between it and the box. With conveyor systems, there are often many ways to reach one solution, but there are often ways that fit certain plants better than others. Regardless, even in a complex space, there is likely a way to solve your box handling woes.

Learn more about Box Conveyor Systems

Contact Vande Berg Scales to Learn More

Singulating Conveyors for Converging Product Lanes

Singulating Converyors, October 24, 2014

When it comes to filling packages, bags, and pouches with batched or small-pieced product, automatic filling systems have become the standard. They make filling fast and consistent, but they can cause some difficulty when it comes to product handling afterwards. A singulating conveyor can solve this problem.

Singulating-Conveyor-Merger

Singulating Conveyor contains individual belts which permit individual product lines to advance while other lines are held back. Once a space opens up, the stopped belts will advance the product. The merging conveyor ensures all products are directed to the center of the belt.

The way most filling machines work is that they fill several packages at a time, which means they are often closely arranged in rows and columns. Having products adjacent to each other on the conveyor makes performing any sort of automatic weighing, labeling, or sorting operations difficult. There are multiple ways of solving this dilemma, but one good way of converging and spacing these products is with the use of a singulating conveyor. To understand the problem, imagine a checkweigher rejecting packages of product.

The checkweigher needs to weigh each package and determine if its weight falls within a certain tolerance. If you have two packages side-by-side, the checkweigher’s weighment becomes invalid. Both would be weighed simultaneously as a “single” product. There is no way to know what either of the packages’ specific weights are so the out-of-spec packages can be rejected. Even if you did, it would be very difficult to reject one or the other. With our singulating conveyors, you can take all of these adjacent packages and automatically arrange them into a single, well-spaced line. The singulator conveyor uses a system of multiple belts and motors so that it has the ability to start and stop different belts independently.

This allows it to move one column of product at a time so that it can eliminate rows of product. They pass onto an out-feed conveyor where product guides can align each package into a neat single-file line. The only problem left is that filling and roll stock machines commonly need to fill different sizes and numbers of bags throughout a day, so the system needs to be able to accommodate variability. This is actually very simple with some adjustments, using the system controls. Presets can allow you to easily switch from singulating two packages side-by-side to three or more side-by-side. This is done by activating different belts at different times, and the transition is virtually seamless. The controller also lets you adjust the time that the singulator will allow between stopping and starting a different set of belts. This permits it to be fine-tuned so that packages aren’t moving too early and jamming with other packages at the product guides. We have a number of systems that relate to filling packaged product because it is a common practice for many companies.

See our Singulating Conveyor

See our Multi-Line Singulator

History of Human Machine Interface & Weight Indicator Combination

History of Human Machine Interface, October 23, 2014

Over the years, our control enclosures and human machine interfaces (HMIs) have evolved drastically. Our long-standing offering, the Scale Data System (SDS) HMI, is a combination of all of the indicator and interface knowledge that we have developed over the years. Now, it is used as the sole foundation for almost all of our new products including checkweighers that we are shipping out, and for good reason. In the past, our old control enclosures used to consist of a simple stainless steel enclosure with a smart (programmable) panel-mounted weight indicator mounted in the face. It did what we needed, but it didn’t offer us the power, programming control, or the user-friendliness that we desired from a color touchscreen.

We also built HMIs that were making use of touchscreens, industrial computers, PCs and industrial controllers, which performed well in all of the categories except for the fact that they had to be interfaced to an exterior simple weight indicator. It just made sense to combine the weight indicator with a smart HMI and process controller that could function as the foundation for many of our systems including our checkweighers and conveyor scales.

Faster Processing = Smaller Footprint

The real advantage for the whole system is the seamless integration of the VBS weight indicator functionality into the SDS HMI. This is important because it allows the system to function at a much higher speed. It processes load cell A-D values at a much greater usable rate, which is roughly 33% more than other leading weight indicators. This means that often conveyor scales can be shorter because the necessary averaging times decrease with the increased processing rate.

The HMI is equipped with a washdown sealed 17” touchscreen monitor which allows easy control and viewing for lant environments. This is a major step up in usability over traditional weight indicators and controls. Using an industrial controller allows us to program the HMI exactly how you need your process to work. Having control of the programming allows us to include features that are non-existent in other offerings and it makes updating a much smoother process.

The SDS still has all of the unique features that our other enclosures are known for, such as rain gutters and foam sealed cable entry for washdown rating. A simple, compact design makes the SDS usable as a standalone system as well as an accompaniment to dozens of other systems besides our conveyor scales and checkweighers. The versatility allows us to make this a regular addition to many products.

See our SDS Video

See our Washdown SDS Industrial Controller

VBS Inc History

Located in Sioux Center, Iowa, since 1964, Vande Berg Scales has built a solid presence in the meat, dairy, food, and manufacturing industry as a leading force in measurement, accuracy, and automation.

Our 15,000 square feet manufacturing facility is located in the heartland of Northwest Iowa.

Automation, Measurement, and Design are our specialties. Currently, VBS Inc. employs over 40 personnel who make up our sales, marketing, administration, production, computer programming, and service departments.

Today, we offer our customers a huge range of weighing, measurement, and automated systems under the brand names: Vande Berg Scales, WeighMore®, Easy-To-Clean™, Ecoline™, and A.S.T.D®.

Vande Berg Scales sells truck scales, agricultural solutions, standard equipment, and we service just about any scale or automated system that needs fixing.