Vande Berg Scales Blog

Welcome to our wonderful blog about Scales!

Call or Email us Today: 712-722-1181 | info@vbssys.com

Washdown Flow Scale Benefits

Washdown Flow Scale, October 22, 2014

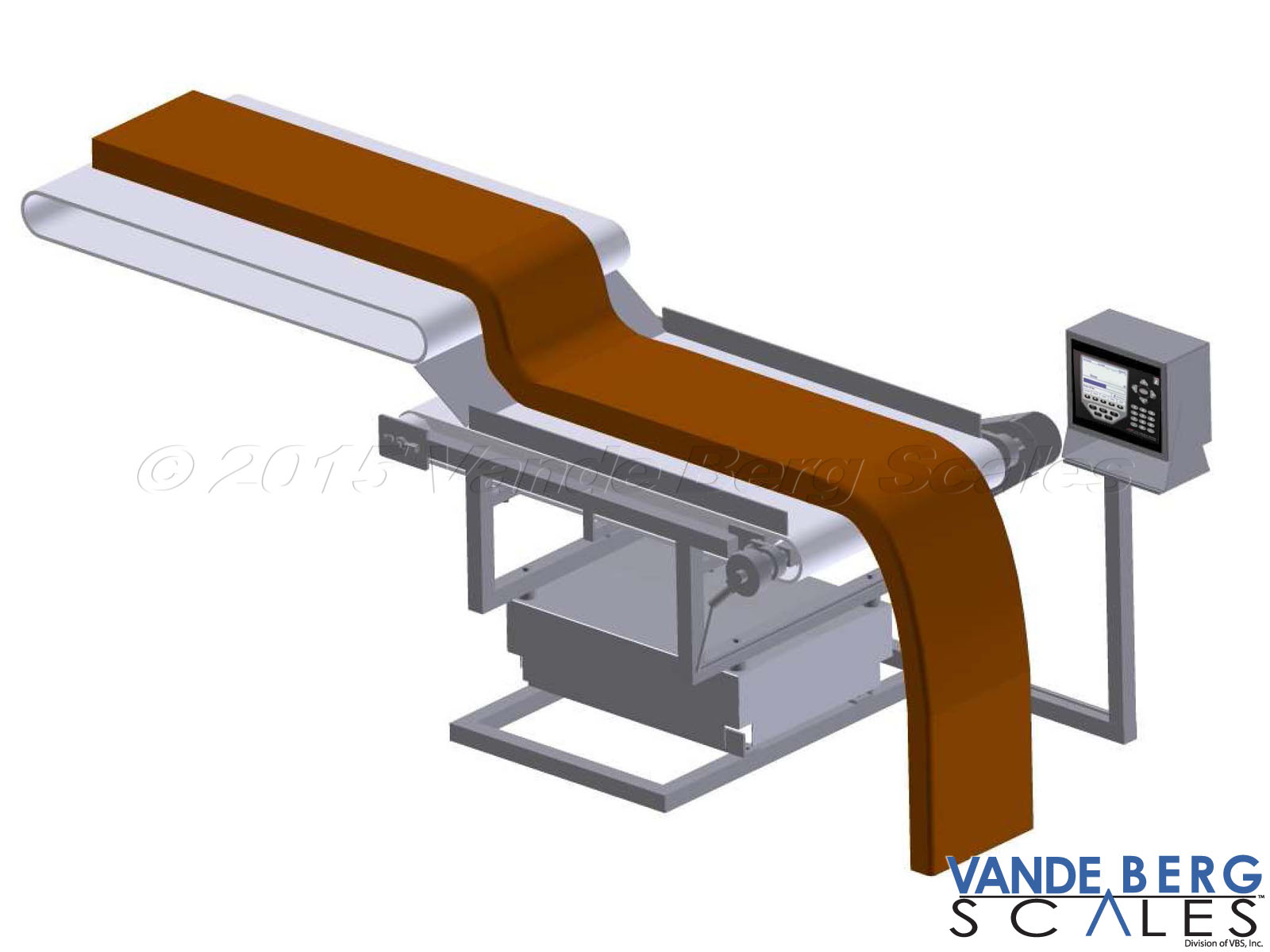

Having a flow scale is great for bulk granular product in order to determine an accumulated weight, but certain products can be far more difficult than others. Some have small grains that can get wedged in tiny spaces and some can tend to stick to machinery. This makes any processes more difficult and working with a flow scale is no exception. For this reason, having a flow scale that is rated for washdown is a major advantage.

When looking at how this improves the flow scale process, we have to inspect some specific products. Use bacon bits as an example. When they are fresh in the plant, they can have moisture that leads them to clump and stick to equipment, which makes them tough to handle. With flow scales, they can tend to stick or leave greasy residue on belting which causes problems. A flow scale takes repeated weighments while it is weighing to get the sum of the product that is passing over it.

The problem with sticky product is that it will add extra weight to the scale conveyor. The little bit of extra weight would seem insignificant by itself, but you have to realize that this weight would be added to the sum every time the conveyor takes a new reading. This can add up to some significant inaccuracy over time.

Washdown Rated

To make the flow scale safe for washdown, we use stainless steel for exposed metal parts. This extends the life of the product by making it sturdy and protected from rust and corrosion. This means that it is also safe from any harsh cleaning chemicals that you might use during your washdown procedures. The structure of the scale is also meant to prevent places for excess water to collect, avoiding possible places for bacterial contamination.

How Existing Data is Integrated Into a VBS System

Existing Data, August 27, 2014

The simplistic answer to this common question is basically that it is a form of electronic copy and paste. When data is maintained in a host data base, our programming department can provide for necessary information to be selected and introduced through a retrieval program. Data is usually maintained in tables such as those in SQL format data bases. A program is written for the respective database to select desired data and place it in an applicable information table for export and use in a system as necessary.

Commonly, weight data from a scale system is simply stored on the indicator and is provided on demand from a program that we have developed on a host computer. This program subsequently provides the communication necessary for data transfer to occur between the indicator and SQL or other database. The type of cabling between hardware may be either serial cable or ethernet cable depending on desired form of communication and speed requirements. As with any project and especially when data integration is required, there should be a thorough review of the overall data process and utilization.

Sometimes, there are artificial boundaries in the form of the left hand unintentionally not interacting sufficiently with the right hand to realize organizational information efficiency. Although information security is of prime concern for operations, it should not be a barrier to a company’s organizational efficiency. Often times, the round table discussions on data needs and use will result in a better understanding and greater appreciation of other operational activities of the company. The end goal is to provide the necessary data when and where it is needed. The data could be integrated in labeling and also required in product tracking and accounting.

How to Optimize Volumetric Filling with In-Motion Checkweighers

Volumetric Filling In-Motion Checkweigher, August 25, 2014

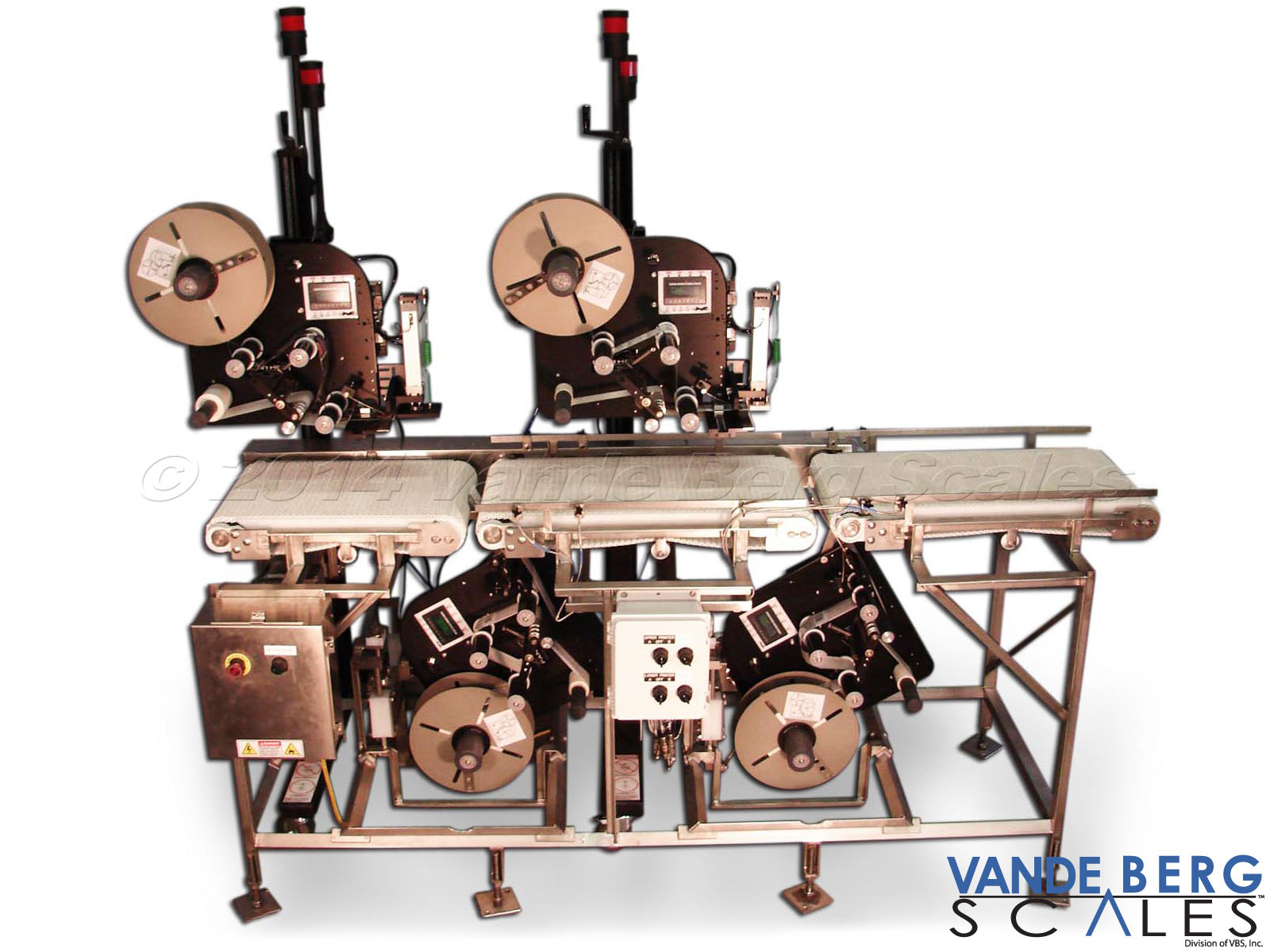

There are generally two ways of automatically filling containers in modern industry: filling by volume and filling by weight. Most filling machines are volumetric in nature, meaning that they output a fixed volume of product into each package or container that they fill. A machine filling by mass would have some sort of scale component, so it is able to weigh and output at a fixed weight. An example of this would be our Net Weight Filler systems.

They use a hopper scale system to output an ideal weight into each container. Ideally, you would want a system that fills by mass because most consumer products (in the case of food at least), are measured or sold by weight. Unfortunately, filling by mass can be very difficult with certain types of filling where a scale would not work well. An example of this is with the machines that fill the packages for beef chubs. They use pressure to extrude a certain volume of product into each plastic wrapping.

While many of these machines are good at staying at a fairly constant volume, correct weight is still not insured because of density. This often depends on how tightly packed a product is. For example, with any product in small pieces, filling by volume to reach net weight might not have the intended effect every time. If product doesn’t settle ideally into gaps and pockets in a package, the net weight of that package might be different than other packages of the same product.

The question then is how you eliminate the problem of products not meeting their intended weight. When combined with an in-motion checkweigher, there is a very intuitive answer to this issue.

If volumetric filling machines aren’t quite hitting the net weight mark for you, you can try running them over an in-motion checkweigher after they are output. You can set up the checkweigher so that it can reject these products and notify you to possibly adjust your filling machine. An even more automatic option could be possible too. By combining the checkweigher and filling machine, you make it possible to make automatic adjustments to output. If the checkweigher system starts receiving a trend of out-of-weight products it can send an automatic voltage signal to the filling machine which can increase or decrease its output to bring the weight trend back into spec.

A solution like this could apply to a great variety of products and a number of industries. Whether you are dealing with beverages, food products, or even something like small toys or parts, an in-motion checkweigher might help you with an efficient resolution to your out-of-weight product woes.

Learn more about our In-Motion checkweigher

Encoding: A Solution For Sorting , Classifying and Labeling

Solution For Sorting, August 21, 2014

When designing a system where a decision is being made by that system’s controller for an action to be taken further down the line, you have two methods to choose from for that controller to make the action happen. One is time-based the other is encoder-based. The time-based option operates very simply. Let’s say that a product is being weighed in motion to determine a certain line that the product should be sent down. Once the products weight has been established by the controller and the appropriate location has been determined, the controller will have been programmed to know that the line is a certain amount of time away, so it will begin counting down, and when that countdown ends, a divert will be activated to send that product down that line.

This is a very simple and effective system as long as nothing ever changes, like line speed. If the line speed is sped up, the product would be past the proper divert before it was activated, and if the line was shut off even for a brief amount of time, all of the timing could be thrown off. To safeguard against this, we like to use an encoder-based system. To explain what an encoder is, basically, the system’s controller will count how many times the shaft on the conveyor turns. Now every system is different but let’s just say that, with this system, every time the shaft turns one time, the conveyor belt will travel six inches. So, with this encoder-based system the controller will have been programmed to know that the divert is a certain number of shaft revolutions away, and all it has to do is count these revolutions and then activate that divert. With this system, speeding things up, slowing things down, or even stopping the system will not affect the process.

That was a very basic description of an encoder. Encoder technology is actually much more advanced than that. In the previously mentioned system, the encoder would send one electrical signal to the system controller for every revolution of the shaft signaling six inches of travel. If this encoder were to send two electrical signals for every shaft revolution, the system’s controller would know that every electrical signal from the encoder would be equal to three inches of travel. Four electrical signals from the encoder would mean each signal would equal one and a half inches of travel. Encoders are available that can send over one thousand electrical signals for each revolution of the shaft. This can allow for very accurate tracking of anything on a conveyor.

See Washdown Sortation Systems

How Trolley Tracking Can Actually Increase Accuracy

Trolley Tracking, August 18, 2014

Trolley tracking systems, like our Trolley Vision®, are being used more and more often for carcass tracking and plant traceability because they are far more reliable than attaching tags to each animal. Whether it is a vision system or an RFID chip in the trolley, trolley tracking is becoming the new standard, but did you know that its benefits don’t necessarily stop at traceability? With Trolley Vision®, we are able to link information directly to each trolley because they are each given a unique ID number. All kinds of different information can be stored in databases and linked to that trolley indefinitely. One little piece of information that could save you money over the long run is the tare weight. The tare weight is simply the weight of the trolley itself, which is subtracted from the overall weight to give you the specific weight of the carcass. In many meat processing plants, the tare is a constant value that is assumed for every trolley. This increases the chance that your final carcass weight could be slightly off. With high volume of production, every little bit counts.

Fortunately, Trolley Vision® can easily keep track of a trolley’s tare weight throughout all of the plant’s processes. All you need to do is run the unladen trolleys over a legal for trade static scale and link that weight to the trolley by running each trolley past a Trolley Vision® camera, so it matches the data to the correct trolley. Having unique tare weights helps you get the most accuracy out of every carcass weighment that goes through your plant. Even if the difference between the assumed tare weight and the actual tare weight is very small, the giveaway costs could stack up over time. With Trolley Vision® reading and storing tare weights, this problem ceases to exist. If you’re interested, Trolley Vision® is capable of improving your plant in a number of different ways that you might not expect right away. Contact us or browse our other Trolley Vision® related blogs and media to find out more.

VBS Inc History

Located in Sioux Center, Iowa, since 1964, Vande Berg Scales has built a solid presence in the meat, dairy, food, and manufacturing industry as a leading force in measurement, accuracy, and automation.

Our 15,000 square feet manufacturing facility is located in the heartland of Northwest Iowa.

Automation, Measurement, and Design are our specialties. Currently, VBS Inc. employs over 40 personnel who make up our sales, marketing, administration, production, computer programming, and service departments.

Today, we offer our customers a huge range of weighing, measurement, and automated systems under the brand names: Vande Berg Scales, WeighMore®, Easy-To-Clean™, Ecoline™, and A.S.T.D®.

Vande Berg Scales sells truck scales, agricultural solutions, standard equipment, and we service just about any scale or automated system that needs fixing.